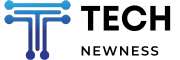

The ongoing revolution in healthcare is increasingly driven by advancements in materials science, particularly the development of conductive inks. These inks are at the heart of cutting-edge medical devices, from wearable health monitors to biosensors and smart prosthetics. By enabling flexible and efficient electronic circuits, conductive inks allow for the creation of devices that improve patient care through continuous monitoring and personalized medicine. This essay explores the importance of conductive inks in medical technology, their role in manufacturing, and the challenges and future directions for this exciting field.

What are Conductive Inks?

Conductive inks are special materials made up of conductive particles—like silver or carbon—suspended in a liquid medium. Silver ink, in particular, is known for its excellent conductivity, making it a key material in flexible electronics. These inks are essential for creating the flexible circuits used in wearable medical devices, biosensors, and even advanced 3D-printed electronics. Companies like XTPL have been pioneers in the development of these inks, offering customizable formulations tailored to specific applications. Their innovations in silver conductive ink, carbon inks, and flexible conductive inks allow medical devices to be both lightweight and adaptable, offering an edge over traditional rigid circuit designs.

What makes conductive inks revolutionary is their ability to be printed directly onto flexible substrates, such as plastics or fabrics. Conductive ink printing is done using techniques like inkjet printing, screen printing, or even advanced methods like 3D printing, where ink is applied in precise layers. XTPL’s advancements in this area are noteworthy, particularly their silver nanoparticle ink, which offers high conductivity and stability—ideal for medical devices that require precise electrical performance. The result is flexible, efficient electronics that can conform to the human body, enabling comfortable, long-term use.

Pioneering Medical Devices Enabled by Advanced Manufacturing

One of the most transformative applications of conductive inks is in wearable health monitors. Devices that track heart rate, blood pressure, or glucose levels in real-time depend on circuits that can bend and stretch without losing functionality. Conductive inks, particularly silver conductive ink, allow for the creation of circuits that remain functional even when flexed. XTPL’s flexible conductive inks play a pivotal role in these devices by maintaining conductivity across various surfaces and ensuring accurate data collection without compromising patient comfort.

Biosensors are another area where conductive inks shine. These devices detect specific biological markers, such as enzymes or proteins, to monitor chronic conditions or provide early diagnoses. The fine resolution achievable with silver nanoparticle ink and conductive carbon ink allows for the development of highly sensitive biosensors. XTPL’s innovations in conductive inks have made it possible to create biosensors that are small, flexible, and biocompatible, making them ideal for continuous use in the body.

Smart prosthetics represent another important application. Conductive inks integrated with sensors allow for more responsive control systems in prosthetic limbs, enabling users to interact with their devices more naturally. XTPL’s silver conductive ink is particularly useful in these applications, as its excellent conductivity ensures smooth signal transmission from sensors to the prosthetic limb, enhancing control and responsiveness. This advancement has improved the quality of life for many amputees, offering them greater functionality and independence.

Challenges and Future Directions

While the potential for conductive inks in medical devices is vast, several challenges remain. Material science innovations are ongoing, with researchers exploring new formulations of conductive inks to improve their conductivity, biocompatibility, and durability. XTPL, for example, has been working on silver nanoparticle ink formulations that can better withstand environmental factors like moisture and temperature fluctuations, ensuring long-term reliability in medical applications.

Scalability is another major concern. While conductive ink printing methods offer precision, scaling up production for mass use in medical devices requires strict quality control. XTPL’s customizable conductive ink formulations address some of these challenges, offering tailored solutions that ensure high performance across different manufacturing processes. However, ensuring that these products meet the rigorous safety and quality standards required for medical devices remains a hurdle.

Looking ahead, the future of conductive inks in medicine is bright. Emerging applications include fully integrated bioelectronic systems, where conductive ink circuits are embedded directly into the body for continuous monitoring or even therapeutic intervention. XTPL’s advancements in 3D printer conductive ink pave the way for complex, multi-layered electronic circuits that can be integrated into medical devices in ways previously unimaginable. For example, XTPL has developed techniques for printing conductive traces directly onto 3D-printed objects, reducing the need for assembly and streamlining the production of intricate medical devices.

In addition, silver nanoparticle ink has the potential to revolutionize neural interfaces, enabling more precise communication between the brain and prosthetic devices or even facilitating new forms of bioelectronic medicine. These innovations could lead to advanced treatments for neurological disorders or create entirely new methods of patient care.

Conductive inks, particularly silver conductive ink and conductive carbon ink, are driving innovation in the development of medical devices. Their ability to create flexible, efficient, and high-performance circuits has made them essential in wearable health monitors, biosensors, and smart prosthetics. XTPL’s customizable conductive ink formulations, including their silver nanoparticle ink and flexible conductive inks, offer tailored solutions that meet the needs of modern medical technology.

As research into conductive ink formulations continues, new opportunities for medical applications will emerge. Whether through improvements in biosensors or the creation of fully integrated bioelectronic systems, conductive inks will continue to play a central role in the future of healthcare. By enabling the development of more flexible, efficient, and lightweight medical devices, conductive inks are at the forefront of innovation in medical technology.

See Also: Ensuring Safety in Chemical Delivery: Key Practices and Compliance Guidelines